Managing a multi-plant ready-mix operation? Feeling the strain of disjointed systems? You’re not alone. Ready-Mix Ordering Systems may be the solution.

By integrating your ERP, batching software, and logistics systems, these ordering systems can turn inefficiency into opportunity. Rather than adding complexity, integrated Ready-Mix Ordering Systems simplify the process, helping multi-plant operations eliminate waste and enhance profitability.

Here’s how.

Mix-Matched Systems Make You Sluggish

Traditional systems often operate in silos. Your ERP handles business management, your batching software takes care of production, and your logistics software manages delivery.

When your ERP, plant batching software, and logistics systems aren’t in synch, even the most advanced operations struggle to keep up.

Adding more software to the mix might not seem like the answer, but implementing a custom Ready-Mix Ordering solution is more than just another piece of software.

Instead of having several different programs that don’t talk to each other, a custom-built Ready-Mix Ordering System powered by GoBuild360 acts as a bridge, connecting all your disparate systems into one seamless flow.

How Do Ready-Mix Ordering Systems Help?

Digital Efficiency:

There’s just no beating technology for making things faster, easier, and more convenient. Just take a look at some of the efficiencies you gain by going digital.

Simplified Quotes, Orders, and Sales:

A GoBuild360 integrated Ready-Mix Ordering System empowers your customers to place their own orders directly into your ERP or accounting system. That gives your customers the freedom and control to specify every detail, from the type of mix to the delivery location.

This eliminates the need for endless phone calls and paperwork, speeding up the process and making the ordering process faster and easier.

Real-time Order Tracking:

Knowing exactly where an order stands is vital for you and your customer. With real-time tracking, a mobile delivery app, and automated e-tickets, both your team and your clients can follow an order from quote, placement, delivery, and payment. And that improves transparency and ensures delay-free payments for everyone.

Profitability:

ROI and Financial Growth:

Investing in a Ready-Mix Ordering System isn’t just about improving operations; it’s about the bottom line. The efficiencies gained through automation lead to significant financial benefits.

For starters, your employees aren’t saddled to their desks with a phone against their ear all day. By automating the steps in the ordering process, your new GoBuild360 Ready-Mix Ordering System reduces the need for manual input.

Now your team can focus on high-value tasks, lowering your overhead and increasing profits on every sale.

Integration:

Unifying ERP, Batching Software, and Logistics Systems:

Perhaps the biggest advantage of a GoBuild360 Ready-Mix Ordering System is its composable nature. Composable systems bring together different parts of your business to operate as a seamless system.

For instance, by linking your ERP, batching software, and logistics systems, your GoBuild360 platform eliminates the silos between these platforms, providing a seamless flow of information for you and your team.

Customization and Flexibility:

Every ready-mix operation is unique, and off-the-shelf solutions rarely fit everyone’s needs. Your new GoBuild360 Ready-Mix Ordering System offers complete customization and flexibility. Now you to tailor the system to your specific requirements.

Our composable architecture ensures your ready-mix ordering solution includes the features your customers demand while providing you with a profitable solution that truly meets your needs.

Key Features of Digital Ready-Mix Ordering Systems

Digital Ready-Mix Ordering Systems are designed to align with the specific needs of multi-plant ready-mix concrete operations like yours.

Here’s a closer look at some of the key features that make these systems so essential— and so profitable:

Order Placement & Processing:

Automated Scheduling and Resource Allocation:

The ability to automatically schedule and allocate resources is a game-changer for operational efficiency. Once a client places an order, the system takes over, streaming information to where it needs to go.

Your GoBuild360 platform populates a delivery schedule based on your available resources. This ensures your customers know exactly what their options are while you allocate the right trucks at the right times so everything is lined up for smooth execution.

This automated scheduling feature not only saves time but minimizes human error, leading to more accurate and reliable deliveries.

Real-Time Tracking:

Client Transparency:

One of the strongest advantages of digital ready-mix ordering systems is how transparent your operation becomes. Customers can log into the system and see exactly where their order is, from the moment they place it to the time it’s delivered.

This level of visibility not only builds trust with clients but also enables better project planning on their end. By allowing customers real-time insights into the status of their orders, Ready-Mix Ordering Systems eliminate uncertainty and provide a new level of control. It’s a feature that not only simplifies the process for the clients but aligns your business with modern expectations of accessibility and customer-centric service.

Project Planning:

Real-time tracking also enables better project planning. Project managers can see when materials are due to arrive, allowing them to schedule other aspects of the construction project accordingly. This minimizes downtime and helps to keep projects on track and within budget.

Communication & Documentation:

Automated Updates:

No more endless phone calls and back-and-forth emails to check order status. The GoBuild360 Ready-Mix Ordering System sends out automated updates, keeping all stakeholders in the loop.

Whether it’s a delay due to weather or confirmation of a delivery time, the right people get the right information at the right time — every time.

Less Paperwork:

Managing paperwork can be a significant drain on time and resources.

Digital Ready-Mix Ordering Systems record every detail of a transaction digitally. This not only means less physical paperwork but creates a clear and concise digital trail that can be accessed when needed. This aids in compliance and makes record-keeping a breeze for everyone in the supply chain.

By automating many of the routine tasks associated with order placement, tracking, communication, and documentation, your new ready-mix ordering system frees up time and resources for you and your staff.

That means you and your executive teams can focus on growth, quality, and strategic decision-making to meet your quarterly objectives.

Real-World Success with Digital Integration

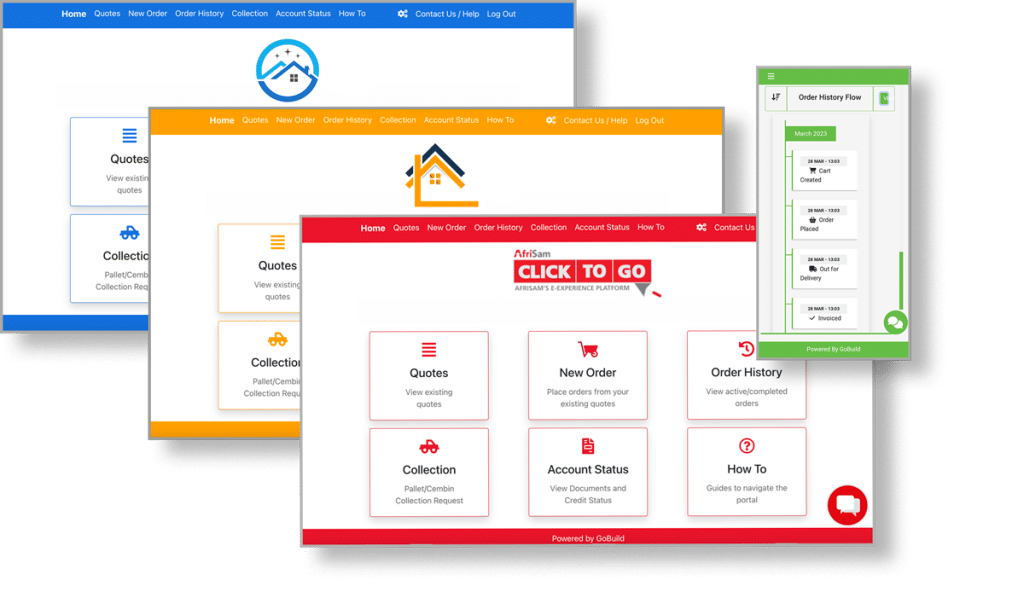

One example of how integrating your disparate systems can make a difference comes from a Global 100 cement and ready-mix producer AfriSam.

After implementing a digital ordering solution powered by GoBuild360, AfriSam’s growth and efficiency skyrocketed.

- ROI of Over 16.23% in the First Year: This figure represents a significant return on investment, demonstrating the immediate financial gains from streamlining operations.

- IRR of Nearly 24%, Climbing Beyond 49% by the Second Year: The internal rate of return growth illustrates how well the investment in digital integration performed over time, outpacing traditional expectations.

Why It Worked:

GoBuild360-powered ClickToGo aligns AfriSam’s ERP, batching software, and logistics.

The custom-built solution integrates their existing systems, slashes processing times, and minimizes total time-to-sale.

Not only that. But by implementing a digital ordering system, AfriSam isn’t wasting its precious human capital on redundant manual tasks. Customer orders log straight into their ERP system. Payments process immediately and the order is automatically routed to operations and logistics.

Instead of manual back-and-forth, fielding email threads and phone calls, AfriSam employees are spending time on high-value tasks, customer service, and sales.

The Result:

A cohesive and efficient operational structure that not only improves daily tasks but leads to impressive financial growth, laying a more robust foundation for long-term success.

AfriSam’s success story is not unique. Many other businesses have already seen similar results. In fact, all one needs to do is look at the data and stats to understand the impact of digital integration halfway through the process.

83.7% Reduced Manual Processes: ????

Automation allowed AfriSam to reduce time and effort spent on otherwise labor-intensive manual tasks across different systems. Now, orders seamlessly transition from customer initiation to operation dispatch, ending up at material delivery without requiring human involvement every step along the way.

119% Increase in Confirmation Rate:????

With real-time tracking and updates, order confirmations turned around faster, increasing the confirmation rate.

72 hours saved per week: ⏳

Automating scheduling and handling customer queries online freed up significant time that could be effectively allocated elsewhere in the business.

Greater Employee Engagement

Team morale improved as employees focused their skills on strategic responsibilities rather than mechanical data entry tasks. Promoting growth and personal development

AfriSam’s success gives you a peek into the power of digitally integrated systems.

But AfriSam’s operation is just one example. Here’s what you need to consider as you transition into this highly profitable space.

Choosing Between Custom-Built and Off-the-Shelf Solutions

For multi-plant ready-mix concrete executives, the decision between custom-built and off-the-shelf Ready-Mix Ordering Systems can be pivotal. Here’s a quick breakdown:

Advantages and Disadvantages:

- Custom-Built Solutions:

- Advantages: Tailored to fit specific business needs, offering more flexibility and potentially greater integration with existing systems.

- Disadvantages: Often more costly and time-consuming to develop and maintain.

- Off-the-Shelf Solutions:

- Advantages: Generally faster to implement and less expensive upfront.

- Disadvantages: May not align perfectly with unique business requirements, potentially leading to gaps in functionality.

Considerations Based on Business Needs and Scale:

- Scale of Operations: Larger operations may benefit more from a custom-built solution that can be precisely aligned with their complex needs.

- Budget Constraints: Off-the-shelf solutions may be more suitable for businesses with tighter budgets.

- Long-term Goals: Consider future scalability and how the system will fit into long-term growth and strategy.

Ready to Implement a Digital Ready-Mix Ordering System? Here’s how.

A. Assess Needs and Objectives:

- Involve IT, Operations, and Sales Teams: To understand the specific needs across your various departments, you’ll need to ask a lot of questions. At GoBuild360, our integration experts collaborate with your entire team to ensure your new system meets the collective objectives. You should do the same.

B. Select a Vendor or Build In-House:

When it comes to implementing an integrated ready-mix ordering system, you have two primary routes to consider: selecting a vendor or building a system in-house.

- Criteria for Vendor Selection: It’s crucial to evaluate factors such as vendor reputation, cost, scalability, support, and compatibility with existing operations. What features and functionalities are essential for your multi-plant operation? Assessing how well a vendor’s solution aligns with your specific needs will guide you in making the right choice.

- Building a System In-House: On the other hand, some companies may prefer the tailored control that comes with building an in-house system. This approach allows for customization that can perfectly align with the unique workflows and demands of your operation. However, it often requires a significant investment in terms of time, technical expertise, and financial resources. The decision to build in-house should weigh these factors against the potential benefits of a system designed precisely for your needs.

C. Integration and Training:

- Successful Roll-Out Strategies: Integration involves not only technological alignment but ensuring that staff is trained and comfortable with the new system. Regular follow-ups, clear communication, and continued support can help ensure a smooth transition.

So no matter which route you take, with the right strategy and focus, your new integrated Ready-Mix Ordering System can become the cornerstone of your efficient and profitable future.

The Future of Ready-Mix Ordering is Digital

The broader movement towards digital transformation in all sectors of the economy means that there will be an increased demand for innovation and greater pressure to adopt digital solutions.

Digital ordering systems streamline your operations by automating your quoting, payments, scheduling, and order tracking. The integration between your ERP, batching, and dispatch software reduces manual intervention and saves time. But that’s not all.

- Enhanced Customer Experience: With an integrated system, your customers get the full digital experience. Immediate account access, and real-time visibility into their orders, from placement to delivery. This transparency builds trust and makes it easy for your customers to buy.

- Sustainability: Digital ordering minimizes the use of paper and supports eco-friendly practices. Efficient scheduling and tracking also mean optimized routes and reduced fuel consumption, contributing to your sustainability goals.

- Scalable and Flexible: As your business grows, your digital systems easily adapt and scale without proportionate increases in complexity or costs.

The Details Are In The Data

- Data-Driven Decisions: Convenient, easy-to-read dashboards uncover hidden inefficiencies. And real-time analytics drive your strategic planning and improvement efforts.

- Integration with Emerging Technologies: With a solid digital foundation, you’ll be ready to integrate with emerging technologies like AI, IoT, LLM, and machine learning, paving the way for continuous innovation.

- Compliance and Regulations: Digital systems offer better compliance with regulations and standards, with automated record-keeping and reporting features. E-tickets, for instance, eliminate the back-and-forth battle with third-party logistics providers (3PL), slashing payment times by at least 60%.

- Resilience and Business Continuity: The COVID-19 pandemic taught us many lessons, one of which was to expect the unexpected. Position yourself to quickly adapt by future-proofing your business systems with a secure, fully integrated digital platform like GoBuild360.

By simplifying complex systems and eliminating bottlenecks, wasted time, effort, and resources, digital Ready-Mix Ordering Systems present a future-oriented solution for multi-plant operations. They represent a path to making businesses not only more efficient and profitable but also more responsive, sustainable, and aligned with modern consumer expectations and regulatory requirements.

Here’s How We Can Help

Are your disjointed systems costing you money?

The development team at GoBuild360 are Ready Mix Ordering System specialists. We’ll integrate your ERP, ordering, sales, batching, dispatch, and logistics systems, turning inefficiency into an opportunity for your business. development

Contact one of our development specialists today and take the first step towards a more efficient, profitable operation.